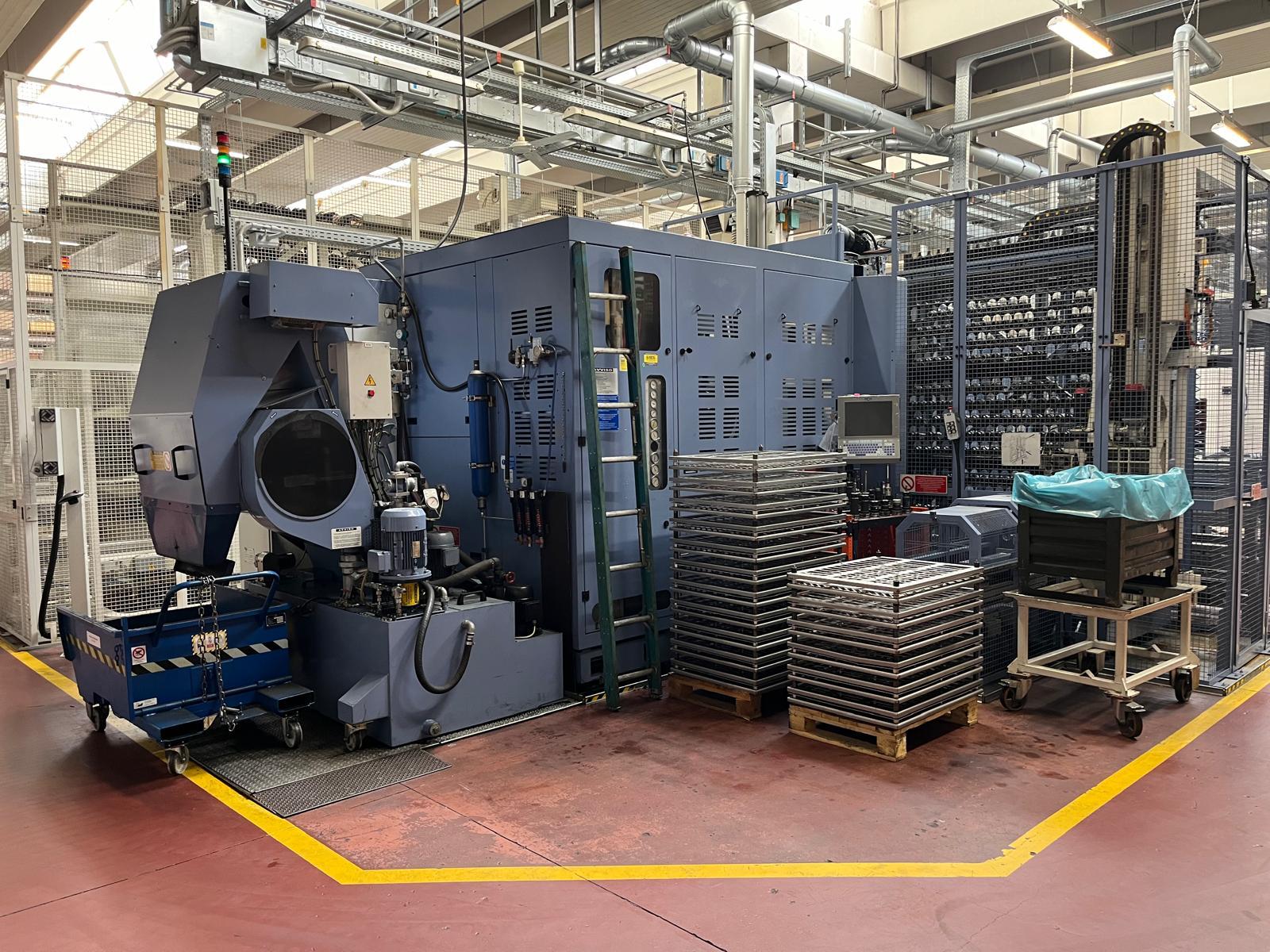

| MANUFACTURER | MCM |

| MODEL | CLOCK 700 MP7 |

| CATEGORY | Horizontal machining center |

| YEAR | 2011 |

| WORKING HOURS | 51.000 |

| CNC CONTROL | Fanuc 16-I |

| MACHINE WEIGHT (kg) | 14.200 kg (without APC) |

| DIMENSIONS (larg. x profondità. x alt.) (mm) | |

| NUMBER OF AXIS | 4 |

| CE DECLARATION | YES |

| SPINDLE | |

| Cone dimension | HSK-A63 |

| Max spindle speed (rpm) | 12.000 |

| Max spindle motor power (cont./30 minuti) (kW) | 25 / 33,8 |

| Head bearing diameter (mm) | 85 |

| Max torque (cont./peak) (Nm) | 159 / 215 |

| CAPACITIES | |

| X axis (mm) | 700 |

| Y axis (mm) | 650 |

| Z axis (mm) | 700 |

| Max piece size (diam. x height) (mm) | Ø 800 |

| TABLE | |

| Dimension (mm) | 500 x 500 |

| Load capacity (kg) | 550 |

| Rotation | Continuous (3.600.000 positions) |

| MULTIPALLET (APC) | |

| Number of station | 6 + 1 |

| Number of loading & unload. Position | 1 |

| Pallet changer | 2 positions |

| Rotation max encumbrance (mm) | Ø 800 |

| FEEDRATES | |

| Rapids X/Z axis (mm/min) | 75.000 |

| Rapids Y axis (mm/min) | 60.000 |

| Max thrust (daN) | 1.000 |

| X,Y,Z axis scale system | Pressurized optical scale (Heidenhain) |

| B axis scale system | Encoder (Heidenhain) |

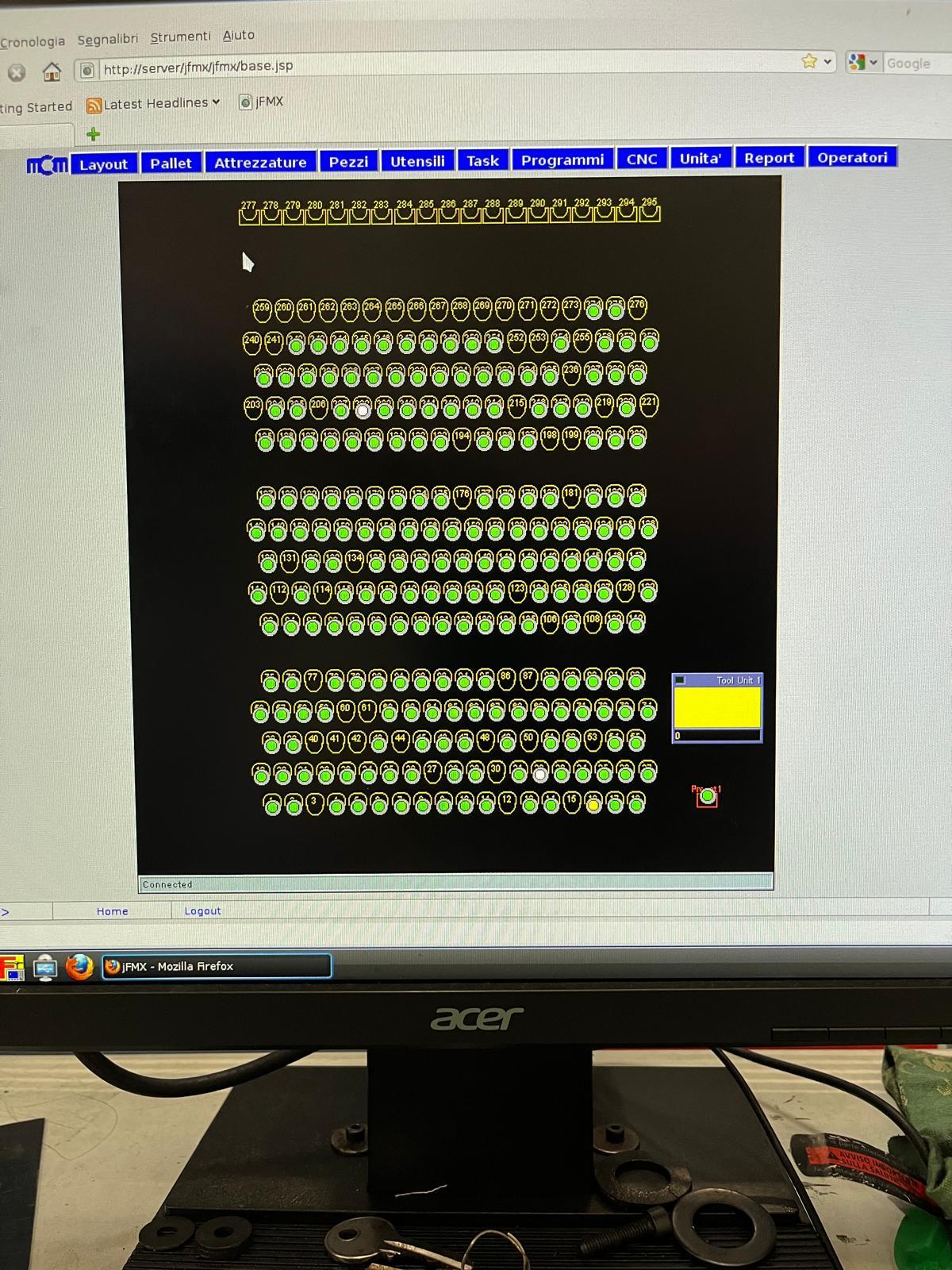

| TOOL CHANGER | |

| Tool cone | HSK-A63 |

| Tool storage capacity | 295 |

| Max tool weight (kg) | 8 |

| Tool change time (chip to chip) (s) | 4,5 |

| Regeneration time (min/max) (s) | 7 – 13 |

| OTHER CHARACTERISTIC | |

| Coolant system for spindle line | |

| Through-spindle coolant system | |

| Air coolant system for the electrical cabinet | |

| Lamp for working area | |

| Internal chip conveyor (auger type) | |

| External chip conveyor (scrape type), rear disposal | |

| Coolant tank: 750 litres with filtering system (3 filters: 500 micro-m and 40 micro-m) | |

| ACCESSORIES | |

| Top cover with mist aspiration set-up | |

| Automatic washing system of the part (activated by M-function) | |

| Tool cone washing system with high pressure coolant (activated by M-function) | |

| Oil separator | |

| High pressure coolant system (65 bar) with continuous variation from 10 to 65 bar | |

| Laser tool presence detection | |

| Compensation of thermal deformation of the spindle (Z axis) | |

| Tool monitor MCM: spindle power measurement (min resolution +/- 100 W) | |

| Marposs probe (MIDA T36) for dimensional measurement and zero part. | |

| Automatic coolant refill | |

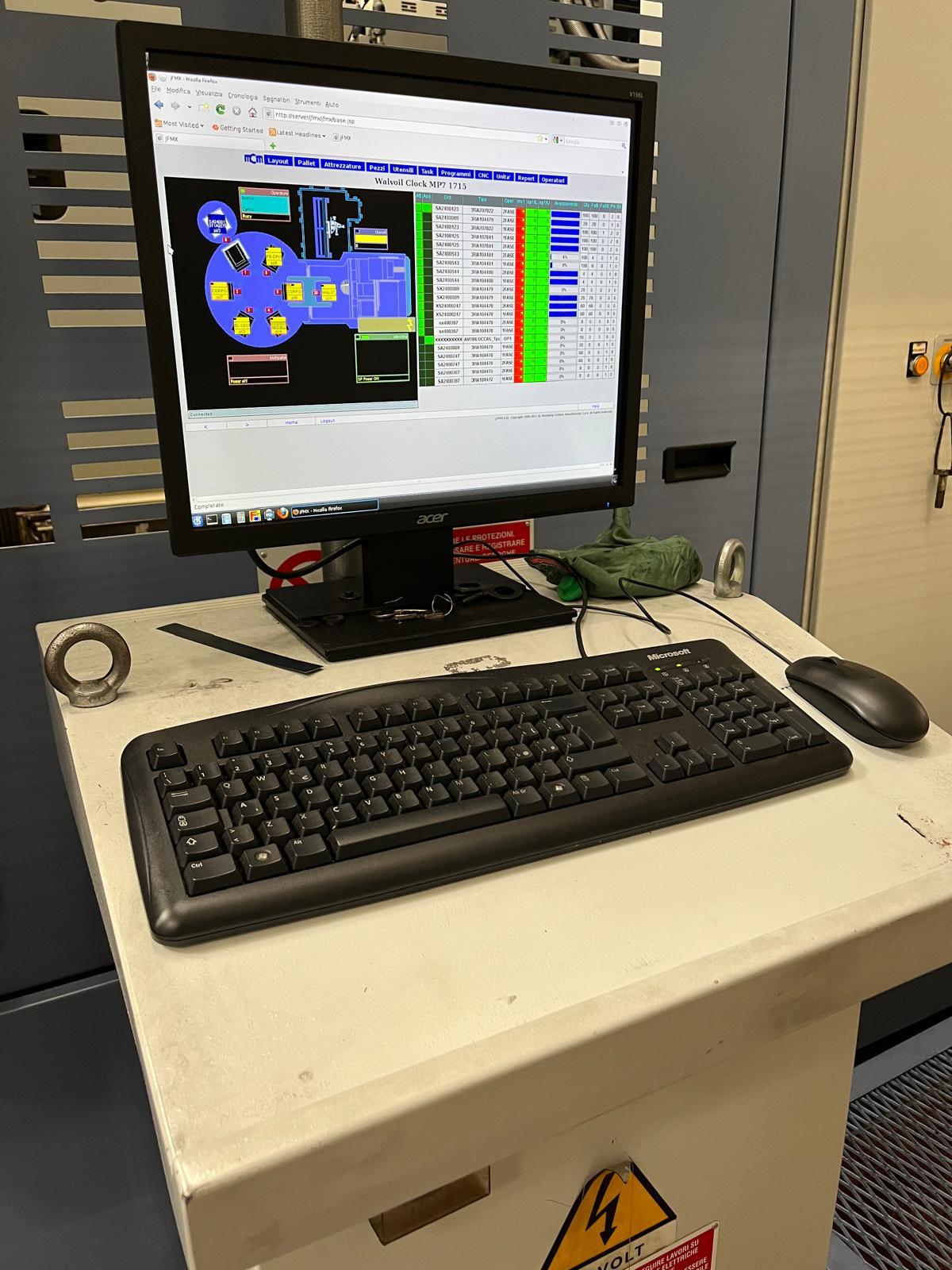

| JFMX supervisor system | |

| – monitor of complete machine and report generation | |

| – manufacturing management | |

| – interface between CAD-CAM and machining center | |

| – remote assistance | |

| – BALLUFF tool management system | |

| – Network Part Progam | |

MCM CLOCK 700 MP7 – anno 2011

Download scheda tecnica completa: (ENG) MCM CLOCK 700 MP7 (Eng)